AutoBB

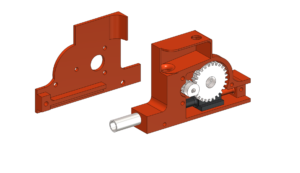

Ideas for a small BB shooter, possibly for a TinyTrak.

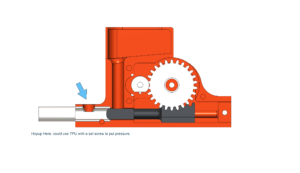

Integrated hopper, auto-feeding, uses single N20 GearMotor. Requires 8x3x4mm ball bearings and M3 screws.

Hopefully someone else can improve on this?

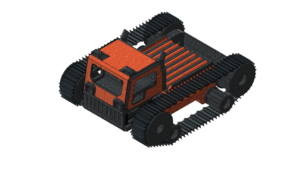

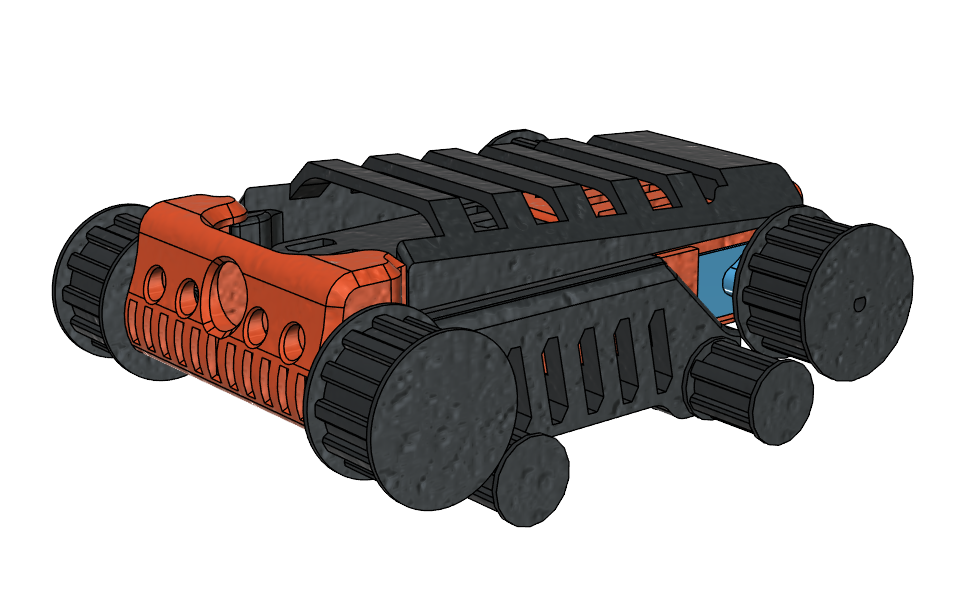

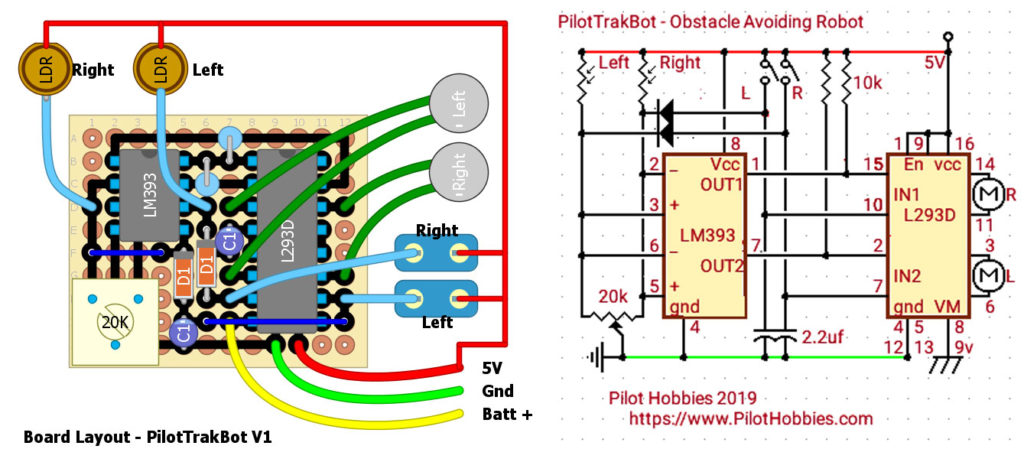

PilotTrak V2 Mini

While the PilotTrak V2 is a huge improvement over the original PilotTrak, it is quite a bit bigger. There’s something about the cuteness of an absolutely tiny tank-like vehicle, and it’s nice to be able to pocket it and go anywhere. Solution? PilotTrak V2 Mini.Continue reading